TG63 - Automatic Control for Graders

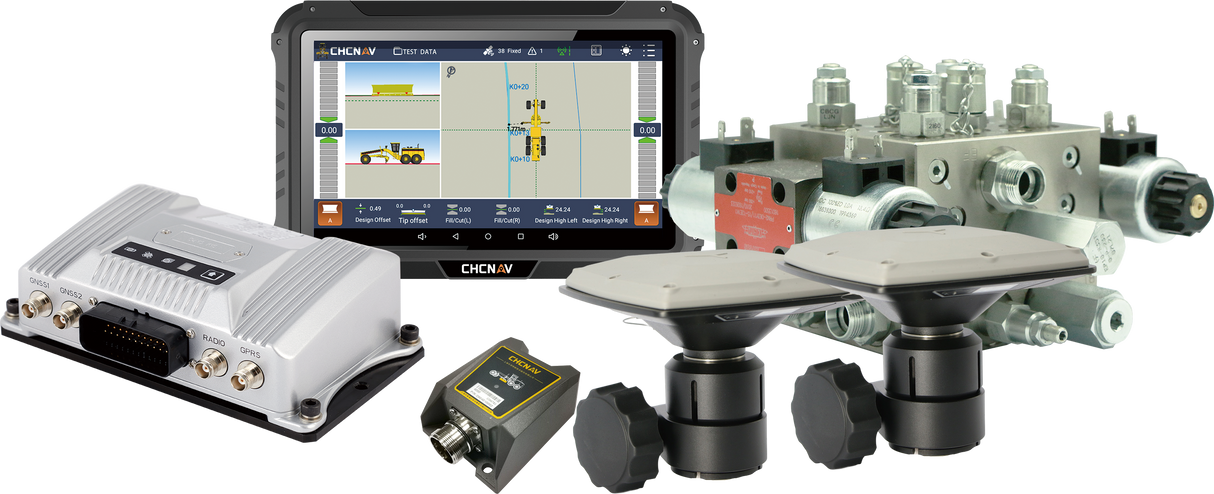

CHCNAV TG63 – 3D Grader Control System for Motor Graders

Precision, Efficiency, and Automation for Grading Operations

The CHCNAV TG63 is a high-precision 3D grader control system designed to automate and optimize motor grader operations. By integrating dual-GNSS, an advanced IMU sensor, and GR-Tech technology, the TG63 ensures ±2 cm accuracy, enabling operators to achieve finished grade faster while eliminating manual staking. Its real-time automatic blade control improves material efficiency, reduces rework, and increases overall productivity on construction sites.

Key Features:

✔ High-Precision Grading – Dual-GNSS + INS positioning with GR-Tech dynamic modeling ensures precise blade control, even on uneven terrain.

✔ Multiple GNSS Correction Sources – Supports RTK, UHF base stations, and NTRIP corrections, adapting to various site conditions for maximum flexibility.

✔ Automatic & Manual Blade Control – Operators can instantly engage or disengage auto mode using cabin-mounted switches, while manual override allows full control when needed.

✔ Fast & User-Friendly Software – GradeNav software on a 10.1” industrial touchscreen provides intuitive controls, supports DXF design files, and simplifies operation for both experienced and new operators.

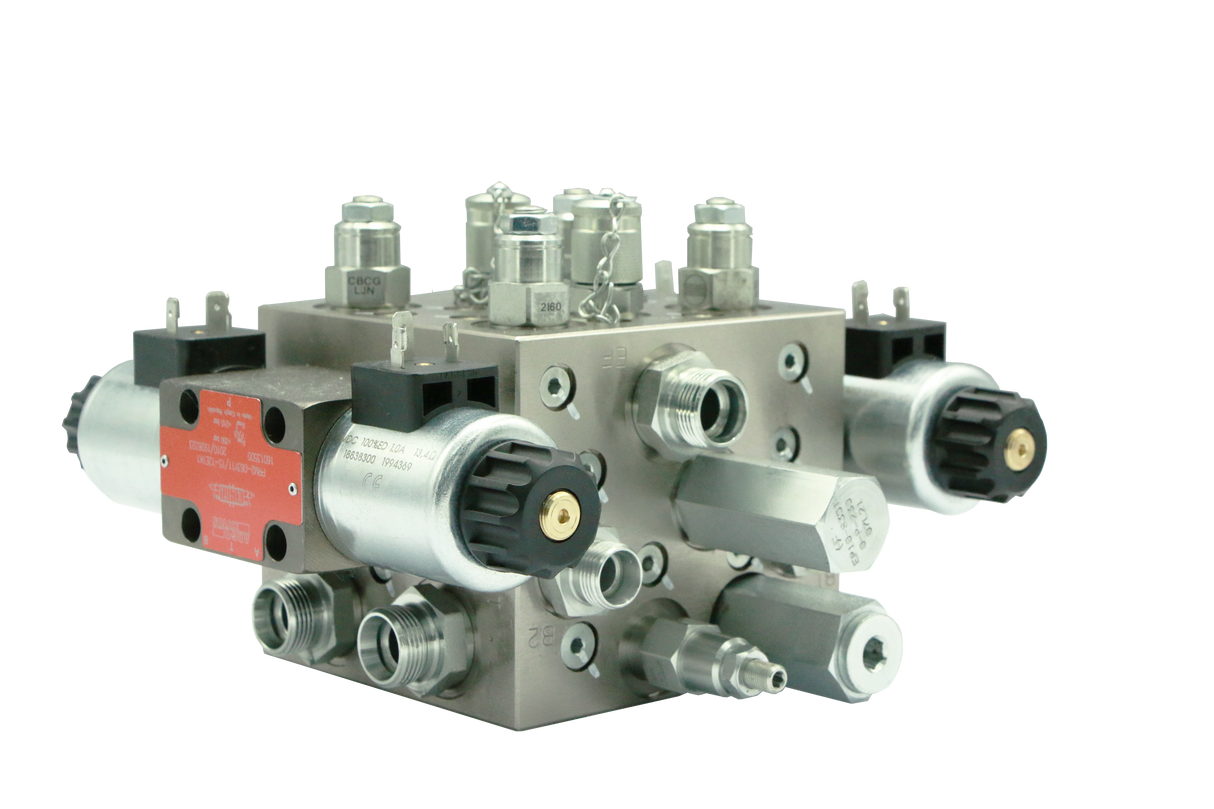

✔ Rugged & Reliable for Harsh Environments – Built with dust and waterproof components, an anti-glare touchscreen, and a high-response valve module, ensuring year-round durability and efficiency.

Why Choose the CHCNAV TG63?

The TG63 is a game-changer for grading operations, providing automated precision, increased efficiency, and reduced material waste. With fast installation, seamless GNSS connectivity, and rugged reliability, the TG63 optimizes every grading project, ensuring faster completion with fewer machines.

Upgrade your grading operations with the CHCNAV TG63 – the smart, automated solution for precision earthmoving.

Diagram

TG63 – 3D Grader Control System

TG63 features

TG63 3D Grader Control System

High Accuracy Automatic Grader Control System